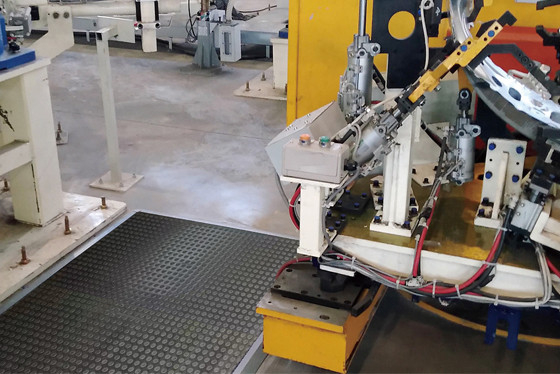

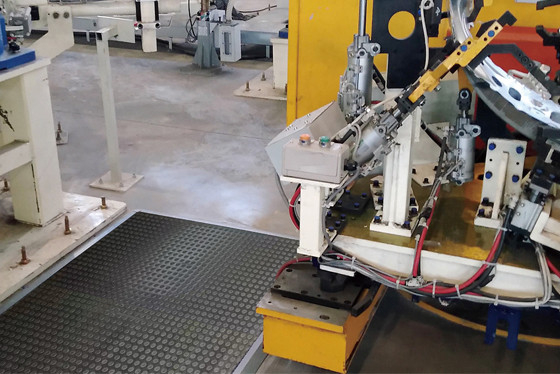

Application Case | A Case Study on Implementing Safety Mat Technology to Improve Industrial Safety

DADISICK si è sempre impegnata in prodotti di sensori di sicurezza di fascia alta, concentrandosi sulla ricerca e sviluppo tecnologico e sull'innovazione di prodotto. I nostri prodotti sono ampiamente utilizzati in settori quali apparecchiature di automazione, produzione meccanica, produzione automobilistica e produzione elettronica, contribuendo a ridurre il tasso di incidenti industriali e a garantire la sicurezza dei dipendenti. Continuiamo a introdurre nuovi prodotti che soddisfano le richieste del mercato, fornendo supporto per la produzione di sicurezza aziendale.

*Servizi di sostituzione: in un mercato altamente competitivo, le aziende devono migliorare continuamente i propri prodotti per mantenere la quota di mercato. Forniamo servizi di sostituzione dei sensori di sicurezza.

*Miglioramento o adeguamento delle linee di prodotto: quando un'azienda entra in nuovi mercati o cambia focus, potrebbe aver bisogno di perfezionare la propria linea di prodotti. Offriamo prodotti di sensori di sicurezza e supporto tecnico per questa transizione.

*Monitorare lo stato di funzionamento delle apparecchiature nel settore dell'automazione , arrestare o regolare tempestivamente le azioni delle macchine per garantire la sicurezza del processo di produzione.

*Monitoraggio della produzione meccanica dei componenti in movimento, prevenzione di potenziali pericoli, salvaguardia della sicurezza dei dipendenti e del regolare funzionamento della linea di produzione.

*La sicurezza nella produzione automobilistica monitora i processi ad alto rischio sulle linee di assemblaggio dei veicoli, migliorando la sicurezza dei lavoratori e l'efficienza della produzione.

*Industria chimica Monitoraggio in tempo reale dell'ambiente di produzione, per garantire la sicurezza nella manipolazione di sostanze tossiche e pericolose.

*Industria alimentare e delle bevande Monitorare il funzionamento delle apparecchiature della linea di produzione, prevenire la contaminazione e lo spreco di cibo.

*Logistica e magazzinaggio Utilizzati per la navigazione AGV e l'elusione degli ostacoli, garantiscono il trasporto sicuro delle merci.

*Nei settori della lavorazione del legno, tessile, della fabbricazione della carta, della stampa, della gomma e della plastica, tra gli altri, i sensori di sicurezza vengono utilizzati per monitorare vari processi di produzione, garantendo sicurezza ed efficienza.