Versatile Ultrasonic Sensors: Output Options and Applications in Industrial Automation

Versatile Ultrasonic Sensors: Output Options and Applications in Industrial Automation

Working Principle of Ultrasonic Sensors

1. Switch output, NO/NC set

3. Digital output: RS485

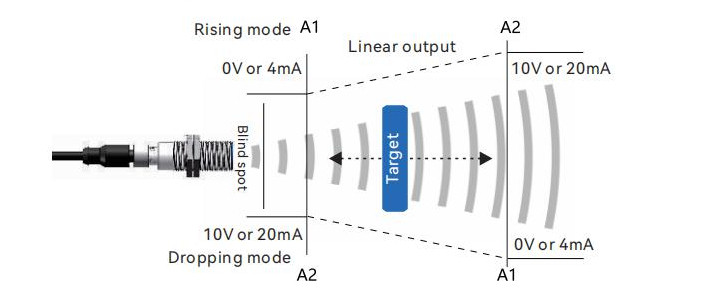

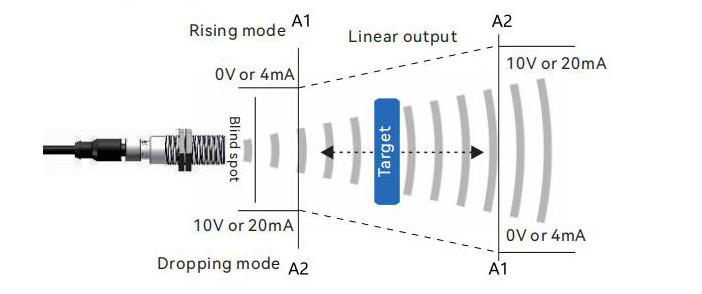

2. Analog output, up/down mode set

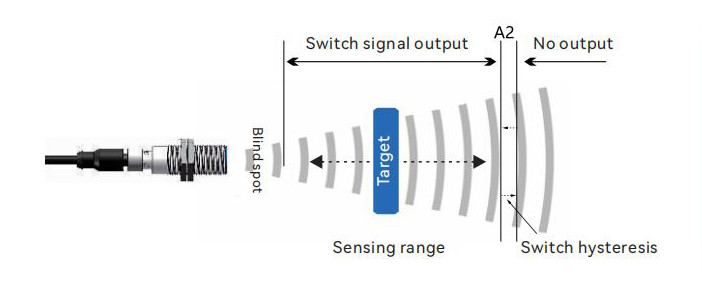

4. Proximity switch mode

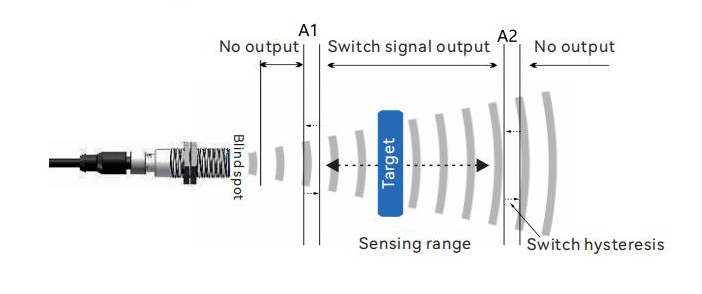

5. Window mode (interval mode)

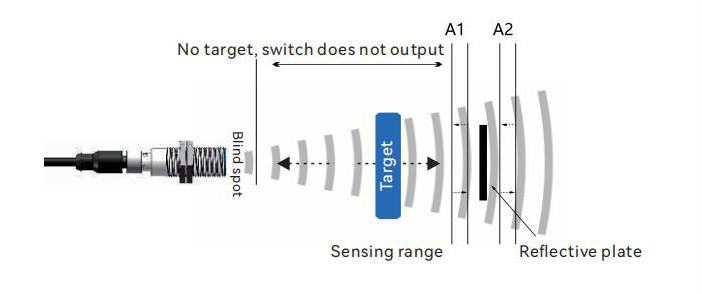

6. Retro-Reflective Mode

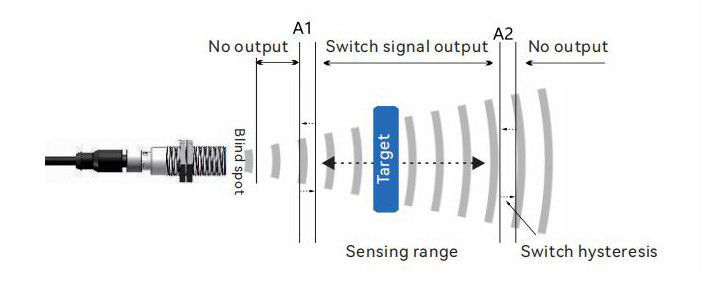

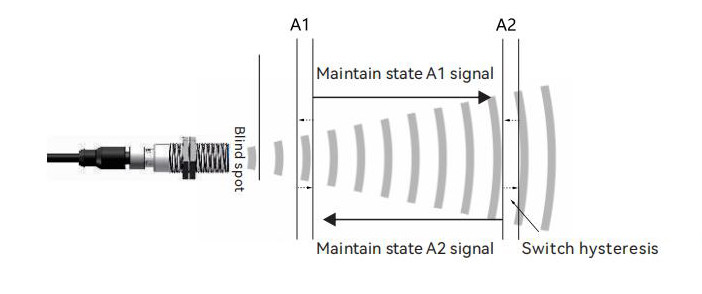

7. Dual-Switch Mode (Hysteresis Mode)

8. Analog Output Mode

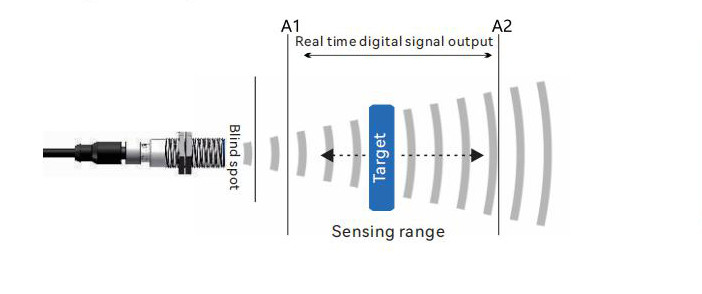

9. Digital Output Mode (IO-LINK, RS232, RS485, TTL, CAN, etc.)

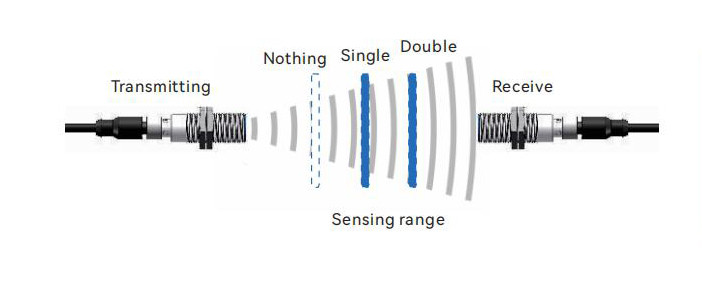

10. Ultrasonic Single and Double Sheet Detection Sensors

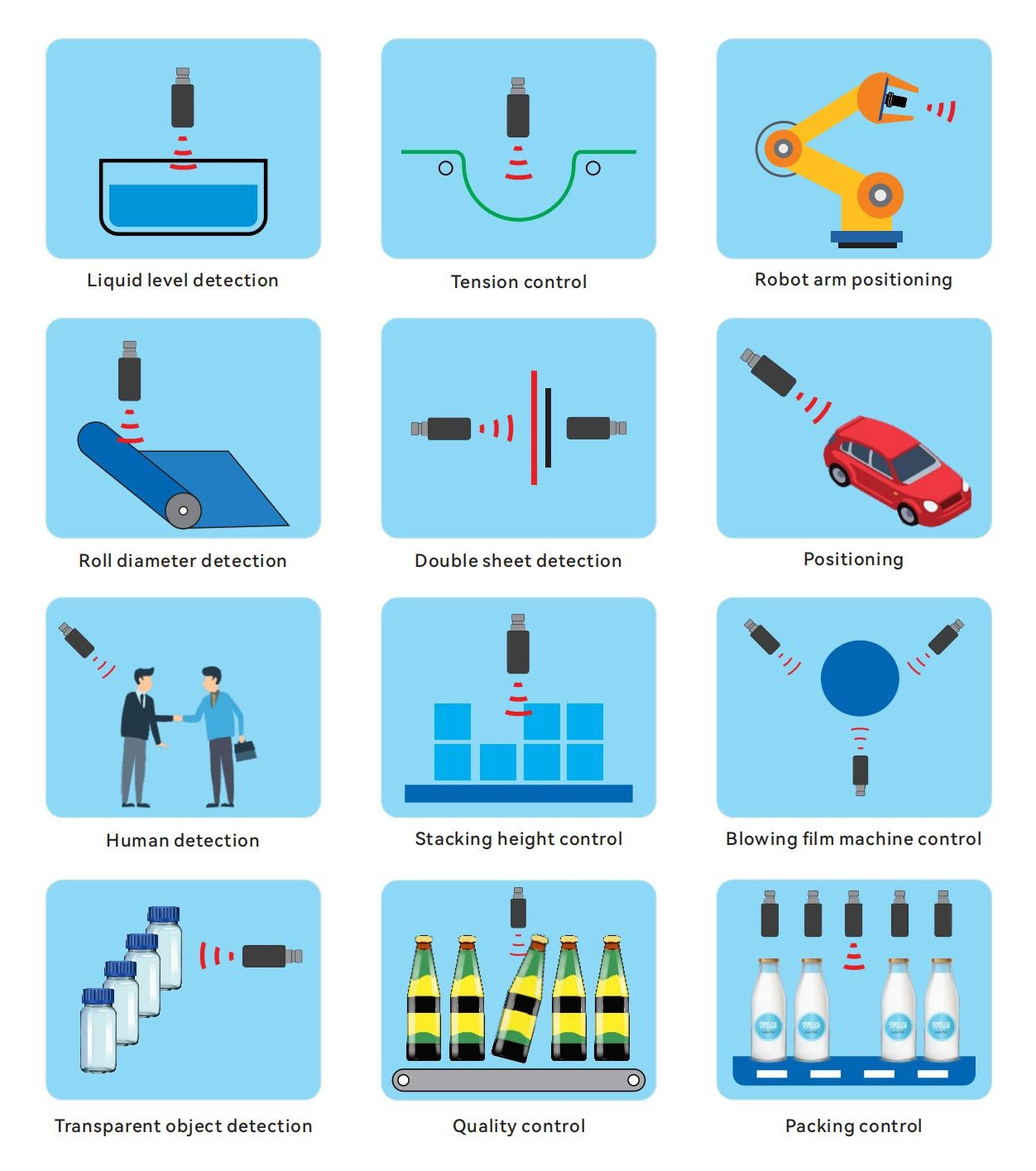

Applications of Ultrasonic Sensors

Wide Applications of Ultrasonic Sensors

Highlights of Ultrasonic Sensors

Monitoring Bulk Material Fill Level

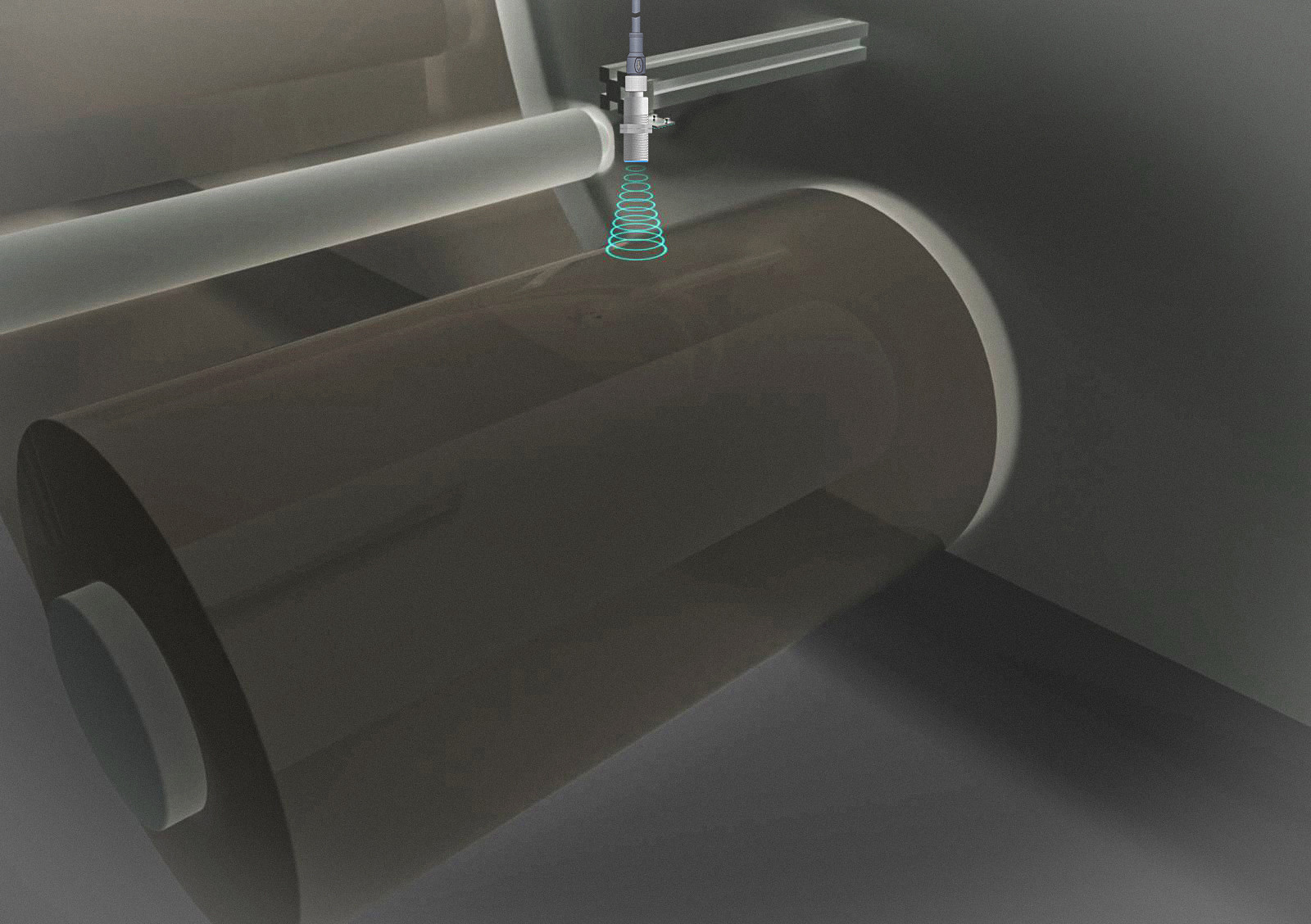

Monitoring Roll Diameter

High-Performance Compact Ultrasonic Sensors for Demanding Applications

|

Models |

CSB12-120

|

CSB12-200 |

CSB18-300 |

CSB18-500 | CSB18-1000 | CSC18-1000 | CSC30-2500 |

|

Detection range

|

20 - 120 mm |

20 - 200 mm

|

30 - 300 mm |

50 - 500 mm | 60 - 1000 mm | 60 - 1000 mm | 150 - 2500 mm |

|

Blind zone

|

0 - 20 mm

|

0 - 20 mm

|

0-30 mm |

0-50 mm | 0-60 mm | 0-60 mm | 0-150 mm |

|

Switching frequency

|

55 Hz

|

45 Hz

|

45 Hz

|

31 Hz | 19 Hz | — | |

Response time | 18 ms | 22 ms | 22 ms | 32 ms | 52 ms | 120 ms | 160 ms |

Hysteresis | 1 mm | 2 mm | — | ||||

Connection type | M12 (4-pin) | M12 (5-pin) | M12 (5-pin) | ||||

|

Models

|

CSB30-2000

|

CSB30-4000 | CSB30-6000 | CSR30-2000 | CSR30-3000 |

|

Detection range

|

100 - 2000 mm

|

200 - 4000 mm | 350 - 6000 mm | 100 - 2000 mm | 150 - 3000 mm |

|

Blind zone

|

0-100 mm |

0-200 mm | 0-350 mm | 0-100 mm | 0-150 mm |

|

Switching frequency

|

10 Hz |

5 Hz | 4 Hz | 10 Hz | 9 Hz |

Response time | 82 ms | 162 ms | 232 ms | 82 ms | 102 ms |

Hysteresis | ±2 mm | ±4 mm | ±5 mm | ±2 mm | ±3 mm |

Connection type | M12 (5-pin) | M12 (5-pin) | |||

|

Models

|

CSDB series

|

Models |

CSDA12-40

|

CSDA18-60 |

CSDA30-100

|

|

Groove depth

|

68 mm |

Detection range |

20 - 40 mm

|

20 - 60 mm |

20 - 100 mm

|

|

Slot width

|

5 mm

|

Blind zone |

5 mm in front

|

7 mm in front |

7 mm in front |

Connection type | M8 (4-pin) | Connection type | 2 m, PVP cable, 0.14 mm² | ||